Latest Projects

Redevelopment Isle of Wight

Project :Product Storage Depot Development(Redevelopment Isle of Wight)

Sector : Liquid Fuel Storage and Distribution

Site : England, UK

Duration : 19 months – From initial concept to client handover

Scope: This project involved the development of a fuel storage and distribution facility on the Isle of Wight, designed to accommodate up to 375,000 litres of various liquid fuels, including Kerosene, Gas Oil, and Diesel.

Trident Engineering provided comprehensive multidisciplinary services, encompassing civil, mechanical, and electrical design. Key project elements included:

- Installation of three 125,000-litre self-bunded tanks, each equipped with a tank gauging system and Independent High-Level Alarm (IHLA) safety system, ensuring robust environmental protection within a secure, impermeable tank farm.

- A 4-arm bottom-loading skid for efficient fuel distribution.

- Integrated drainage spill zones connected to a Class 1 interceptor for effective spill containment.

- An underground attenuation system to enhance water runoff rates and bolster the site’s drainage infrastructure.

- Construction of a modular office building and designated parking areas for staff and visitors.

The project spanned all stages from site planning and contractor selection to procurement, construction, and commissioning, resulting in a fully compliant, efficient, and high-quality fuel storage facility.

Liquid Fuel Storage

Project : Diesel Storage Tanks and Operating System Replacement

Sector : Liquid Fuel Storage – Manufacturing Test Facility

Site : England

Duration : 10 months – From initial concept to client handover

Scope: Trident Engineering was appointed as the Principal Designer and Project Manager for the replacement of two diesel and petrol tanks that supply a test facility in the manufacturing sector. This project encompasses the development of a new concept design and operating system tailored to the client’s needs. Additionally, a staged installation program was implemented to ensure that production remained unaffected.

Throughout the project, Trident Engineering adopted a comprehensive approach, encompassing the full client brief and integrating multidisciplinary expertise in mechanical, electrical and system design. Key project components included:

- Replacement of aging 50,000 litre and 20,000 litre fuel tanks: Isolate, drain, and remove from the site for scrappage in accordance with environmental legislation. A crane supplied with a lift plan was used, and road transportation was arranged.

- Existing bund was repaired and lined with fiberglass membrane.

- Staggered Program was scheduled so as not to impact production.

- 20,000 litres tank was removed initially with existing 50,000 litre tank remaining online and replaced with a new 18,000 litre tank, new operating system was installed along with a Tank gauging ,(IHLA) Independent High level Alarm system for added safety and loading header system were all constructed , connected to existing Double walled underground pipework and commissioned

- 50,000 litre tank was removed and replaced with a New 40,000 litre tank

- Transfer system was integrated to transfer product from one tank to another.

- New Tank integrated into existing system and commissioned

The project encompassed all phases, starting with the initial site visit and client meetings to determine the scope. It included Stage 4 budget estimation, tendering, contractor selection, procurement, construction, commissioning, and final site sign-off and handover. The result was a high-quality, efficient, and fully compliant, state-of-the-art facility.

Norwich Demolition

Project : Product Storage Depot Decommissioning

Sector : Demolition

Site : England, UK

Duration : 7 months – From initial concept to client handover

Deliverables:

- Cost estimation and budget control

- Creation of depot decommissioning drawings

- Submission of demolition planning application

- Contractor evaluations and appraisals

- Preparation of tender packages for tank cleaning, electrical isolation, and demolition works

- Tender analysis

- Development of a construction phase plan

- Review of contractor risk assessments and method statements

- Creation of a detailed program of works

- Provision of a fully qualified Trident site manager to oversee tank cleaning, electrical isolation,

- and demolition phases

- Weekly progress reports to stakeholders

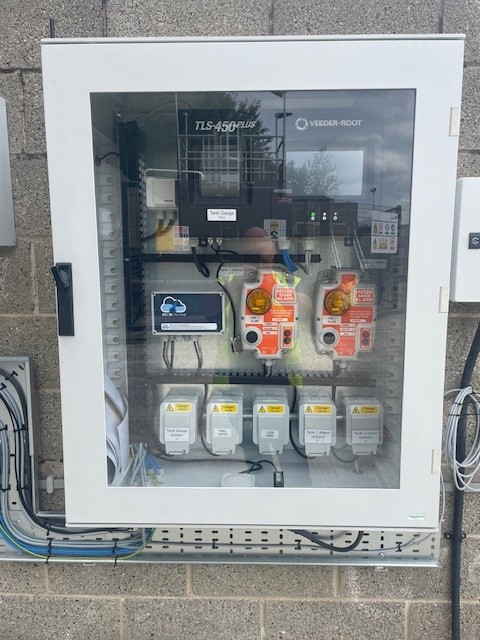

Norwich Development

Project : Product Storage Depot Development

Sector : Liquid Fuel Storage and Distribution

Site : England

Duration : 28 months – From initial concept to client handover

Scope: Trident Engineering was appointed as the Principal Designer for the development of a 6,500m² fuel storage and distribution facility located in Norwich. The facility is designed to accommodate up to 750,000 litres of various liquid fuels, including Kerosene, HVO, Gas Oil, Diesel, and Therma 35.

Throughout the project, Trident Engineering provided comprehensive multidisciplinary services, integrating civil, mechanical, and electrical design expertise. Key project components included:

- Installation of six 125,000-litre self-bunded tanks, each equipped with a tank gauging system and Independent High-Level Alarm (IHLA) safety system, all housed within a secure, impermeable tank farm.

- Two bottom-loading skids for efficient fuel distribution

- Integrated drainage spill zones connected to a Class 1 interceptor for effective spill containment.

- Construction of a modular office building and designated staff parking area.

The project covered all phases, from site planning and contractor selection to procurement, construction, and commissioning, resulting in a high-quality, efficient, and fully compliant fuel storage depot.

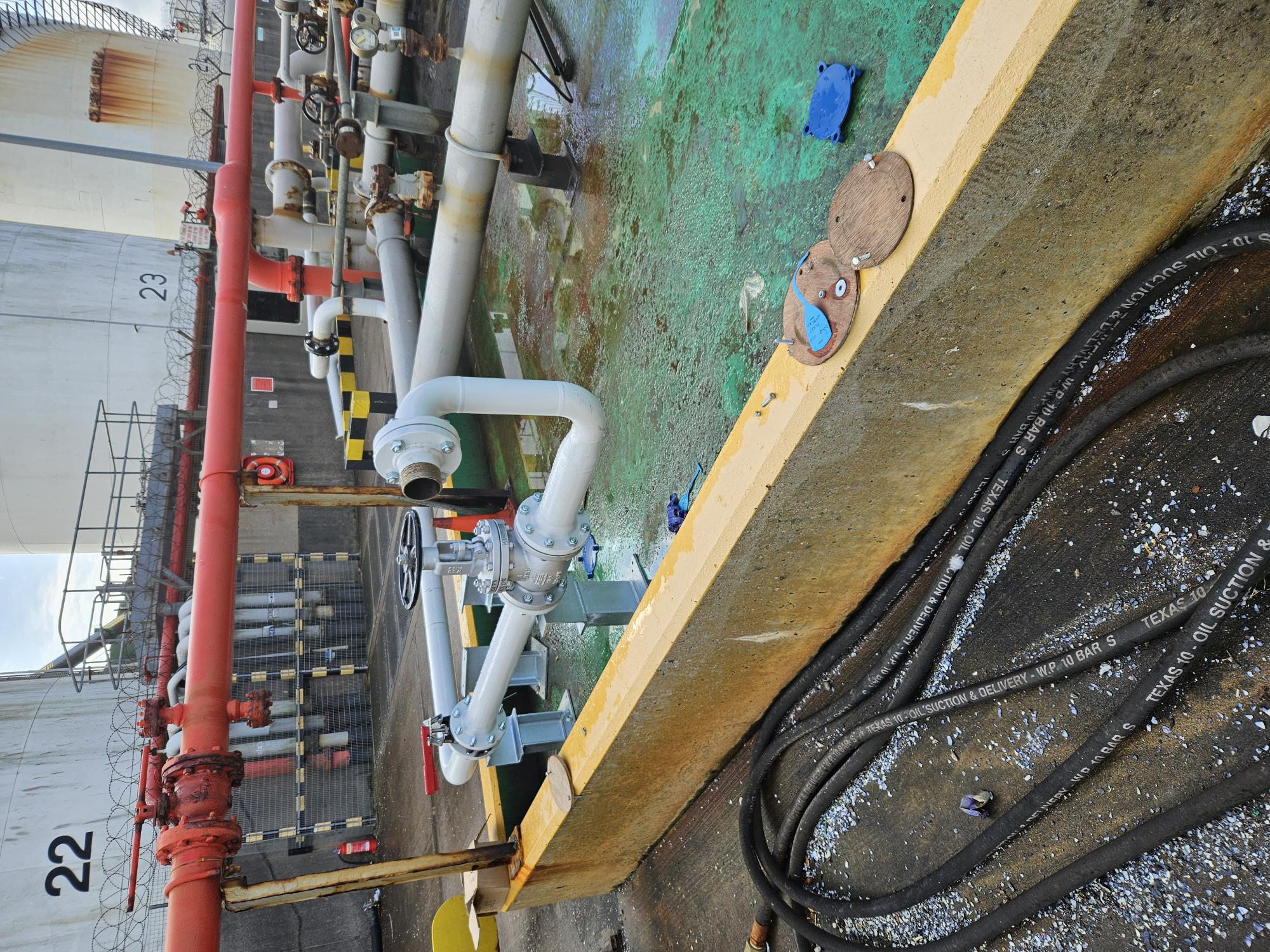

Depot Redevelopment Portsmouth

Project : Product Storage Depot Redevelopment

Sector : Liquid Fuel Storage and Distribution

Site : England,UK

Duration : 17 months – From initial concept to client handover

Scope: Trident Engineering served as Principal Designer for the redevelopment of an existing fuel storage and distribution facility in Portsmouth. The upgraded site was designed to store up to 625,000 litres of various liquid fuels, including Kerosene, HVO, Gas Oil, Diesel, and GTL.

The project commenced with the demolition of the old facility, which Trident Engineering managed. Throughout the redevelopment, we provided multidisciplinary services covering civil, mechanical, and electrical design. The key upgrades included:

- Installation of five 125,000-litre self-bunded tanks, each equipped with a tank gauging system and Independent High-Level Alarm (IHLA) safety system for enhanced environmental protection. The tanks were housed within a secure, watertight tank farm.

- A five-arm bottom-loading skid for efficient fuel distribution.

- Integrated drainage spill zones connected to a Class 1 interceptor for effective spill containment.

- Underground attenuation tanks to improve water runoff rates and overall site drainage management.

- New product pump dispensers and pipework to upgrade the existing HGV refilling facility.

Additionally, the development involved the construction of a modular office building and parking areas for staff and visitors. Trident Engineering managed all project phases, from site planning and contractor selection to procurement, construction, and commissioning. The result was a highly efficient, fully compliant fuel storage depot.

Government Infrastructure Project

Project : Product Storage and Fuel Distribution Facility Development

Sector : Liquid Fuel Supply to Facilitate a Government Infrastructure Project

Site : England,UK

Duration : 15 months – From initial concept to client handover

Scope: Trident Engineering was selected as the Principal Designer for a significant government infrastructure project involving the development of four specialized sites for liquid fuel storage and distribution. Each site was equipped with two tanks, providing a total storage capacity of 135,000 litres, along with forecourt dispensers and high-speed bowser fill capabilities. These facilities are designed to handle various liquid fuels, including Diesel and AdBlue.

Throughout the project, Trident Engineering provided comprehensive multidisciplinary services, integrating civil, mechanical, and electrical design expertise. Key project components included:

- Installation of one 125,000-litre self-bunded Diesel tank along with a 10,000- litre AdBlue tank both equipped with a tank gauging system with remote monitoring

- Detailed Civil design with Tank Base ,Integrated drainage spill zones connected to a Class 1 interceptor for effective spill containment.

- Installation of distribution system consisting of Four twin dispensers along with Two Bowser Fill skids for efficient fuel distribution controlled by a self-service card reading fob system.

The project covered all phases, from site design, contractor selection to procurement, construction, and commissioning, resulting in a high-quality, efficient, and fully compliant fuel storage , distribution facility

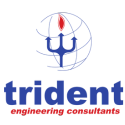

Independent High Level Alarm system (IHLA)

Project : Independent High Level Alarm system (IHLA)

Sector : Liquid Fuel Storage

Site : England,UK

Duration : 6 months – From initial concept to client handover

Scope: Trident Engineering has been appointed as the Principal Designer for the installation of an independent high-level alarm system. This system aims to enhance safety and mitigate the risk of overfilling at an existing site’s multiple tank farm. The project encompasses the Safe working capacities ,integration of electrical panels with remote touch screen controls, tank instrumentation, and automatic closure motorised valves

Throughout the project, Trident Engineering adopted a comprehensive approach, encompassing the full client brief integrating multidisciplinary expertise in mechanical, electrical and system design. Key project components included:

- Design, installation and commission of an automatic Tank Hi-Hi system with automatic valve closure when designated level is reached , considering all Hazardous Areas and conforming with current Atex legislation

- Producing and calculating a Tank Alarm schedule with process and Cause and effect diagrams

- Installation of a state-of-the-art HMI touch screen control system

- Intrinsically safe instrumentation which is SIL rated along with Atex Rated Motorised valves

- Multiple beacon sounders situated around site to bring attention to the Hi-HI been triggered.

- Self-Testing system with automatic fault reporting built into design enabling the maintenance costs to be reduced.

- Power outage back-up system with Uninterruptible power supply ( UPS ) connected to a critical services power distribution system, designed to accommodate the addition of existing gauging systems

Trident Engineering managed all project phases, from design and contractor selection to procurement, construction, and commissioning. The result was a functioning highly efficient up to date safety system to reduce the risk of tank overfill

Storage tank replacement

Project : Storage tank replacement

Sector : Liquid Fuel Storage and Distribution

Site : Shetland Isles

Duration : 15 months – From initial concept to client handover

Scope:

Trident Engineering was appointed as consultant to assess the fitness of purpose of a 1000m3 tank on unleaded duty within an operational storage terminal.

The asset had a history of pin hole defects on shell courses with presence of numerous damp marks on weld seams.

A shell survey in accordance with EEMUA 159 was carried out which revealed an asset at the end of life with poor containment integrity.

A risk based approach was adopted in providing a value engineered solution to our client resulting in minimal asset downtime and adverse business effects.

The key project works undertaken:

- EEMUA 159 fitness for purpose assessments

- Tank decommissioning

- Tank designs to EN14015

- Tank construction works

The project covered tank inspection, tank assessment, asset demolition, tank design, contractor selection and appointment, new tank build and site supervision. Trident was involved through the project life cycle from inception to handover.

HVO Product Conversion

Project : HVO Product Conversion

Sector : Fuel Distribution Terminal

Site : Aberdeen,Scotland

Scope: Trident Engineering was commissioned to manage the full project lifecycle—from initial design to handover—for the introduction of HVO (Hydrotreated Vegetable Oil) import and export operations at the facility. This included the integration of new equipment and the adaptation of existing storage.

Key aspects of the project included:

- Repurposing a 3.33-million-litre storage tank, previously used for a different product, for HVO storage. The tank underwent thorough cleaning, inspection, and repair before being utilised.

- Importing HVO into the tank from the quayside using a combination of new and existing pipework.

- Installation of new pipework to facilitate a bunkering operation for marine services and support a gantry operation utilising an existing loading arm to fill road tankers.

- Installation of two new 55kW pump sets on existing bases for bunkering and gantry operations. The pumps were precision laser-aligned and vibration-checked before being put into service.

- Upgrading existing soft-start units and starters in the switchroom to comply with current regulations, while retaining the majority of the existing cabling for cost-effectiveness. Additional signal cabling was installed to connect the switchroom PLCs with the new equipment.

- Enhancing quayside lighting for improved visibility during bunkering and general maintenance, based on a comprehensive lighting survey and design.

.jpg)

.jpg)